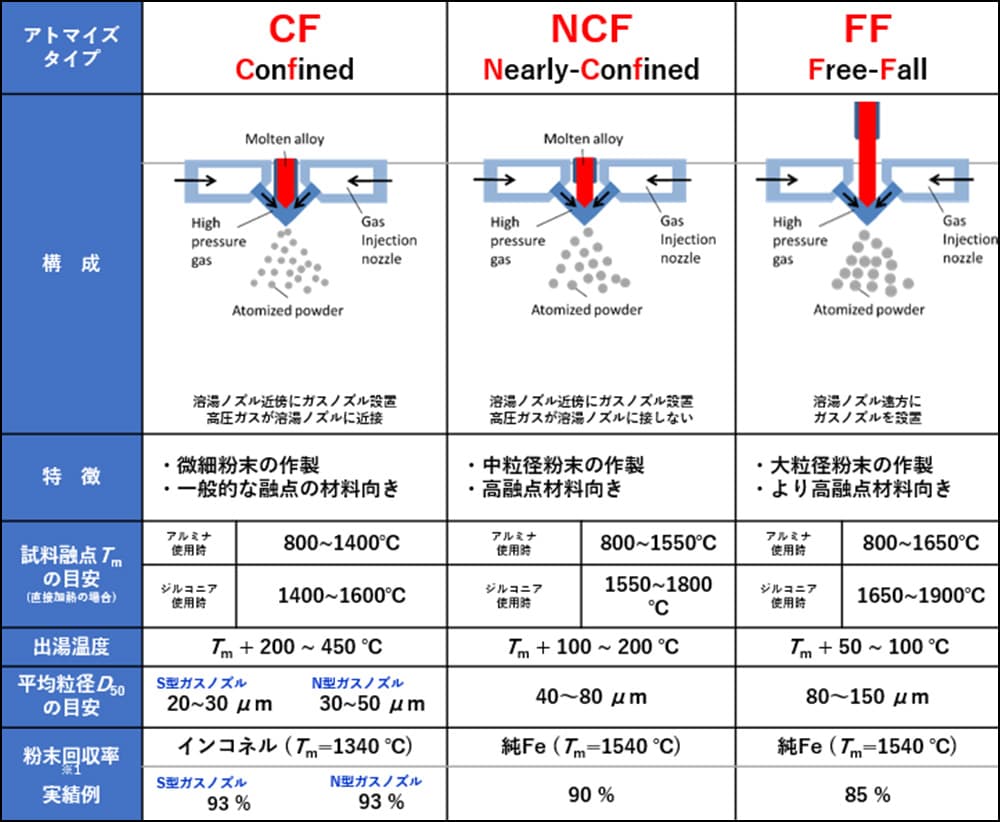

真空排気後、 不活性雰囲気中で、高周波誘導加熱により金属を溶解します。溶解チャンバーと噴霧チャンバー間に差圧を生じさせ、且つ、ストッパーを上昇させることにより溶解金属を下方に落とします。その溶解金属に高圧ガスを噴きつけ、球状の金属粉末粒子を作製します。酸素濃度100ppm以下の環境で急冷凝固粉末化する為、酸化性の強い試料でも容易に球状粉末化させることができます。

特性

- 平均粒径20~150μm粒径分布制御

- 独自開発による高性能ガスノズル

- 過去1300回以上のテストデータ蓄積

- 高粉末回収率 (90%以上)

- 出湯条件選定サポート

- オペレーション自動化

仕様

- 溶解量

- 鉄換算1~20kg,60kg

- 出湯温度

- ~1750℃

- 噴霧ガス種

- Ar、N2

- 噴射ガス圧(最大)

- 9.0MPa

※ご要望にあわせ装置設計をいたします。

実績

Fe系、Ni系、Al系、Cu系、Li系、Si系、Mn系、Co系、Ag系、Sn系、Mg系、Zn系、Nd-Fe-B、Sm-Fe、SUS316、64Ti、インコネル、純鉄

動画

-

ガスアトマイズ装置

-

ガスアトマイズ装置の遠隔操作と自動運転

オペレーション自動化システムを搭載し、ネット環境が備わっていれば自宅でも遠隔操作が可能です。真空~加熱~出湯の自動運転、データベースサーバへの自動保存が可能となり、技術継承も容易です。

ガスノズルタイプ

-

CF-S(微粒粉砕用コンファインド型)

冷却速度向上(噴霧ガスの流速)のため、シュリーレン法を用い保有するガスノズルの気流を可視化いたしました。

独自開発のガスノズルと蓄積した過去1300回以上の実験データより、ご要望組成の粉末が得られるよう開発に取り組んでおります。

小型ガスアトマイズ装置

- 溶解量

- 鉄換算200g

- 粉末回収率

- 90%程度

- 最大出湯温度

- 1700℃

- 噴霧ガス種

- Ar、N2

- 噴射ガス圧(最大)

- 9.0MPa

※ご要望にあわせ装置設計をいたします。

超小型ガスアトマイズ装置

- 溶解量

- 鉄換算50~100g

- 粉末回収率

- 70%以上

- 最大出湯温度

- 1500℃

- 噴霧ガス種

- Ar、N2

- 噴射ガス圧(最大)

- 9.0MPa

※ご要望にあわせ装置設計をいたします。